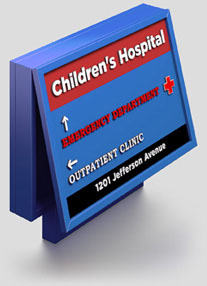

The Series 1200 is an architectural signage system from Charleston Sign Manufacturing that provides substantial dimensional. It features a full 12″ depth and is best suited for use as a primary signage. The Series 1200 comes in illuminated or non-illuminated options, as well as solar configurations.

The Series 1200 has an integral hinge system that allows for easy and quick maintenance of the cabinet and its internal components. It also has a recessed and skirted base that makes landscaping and maintenance easy. The Series 1200 accommodates aluminum, polycarbonate, acrylic, or pan-style faces. All components of the Series 1200 are finished after fabrication to ensure a uniform appearance and eliminate bare edges.

FINIALS

Standard finial options available on 218, 225, 250, 325 and 750 series.